3D Bioprinting at the Frontier of Medical Innovation

A theoretical scientist and an experimental engineer join forces to solve public health issues.

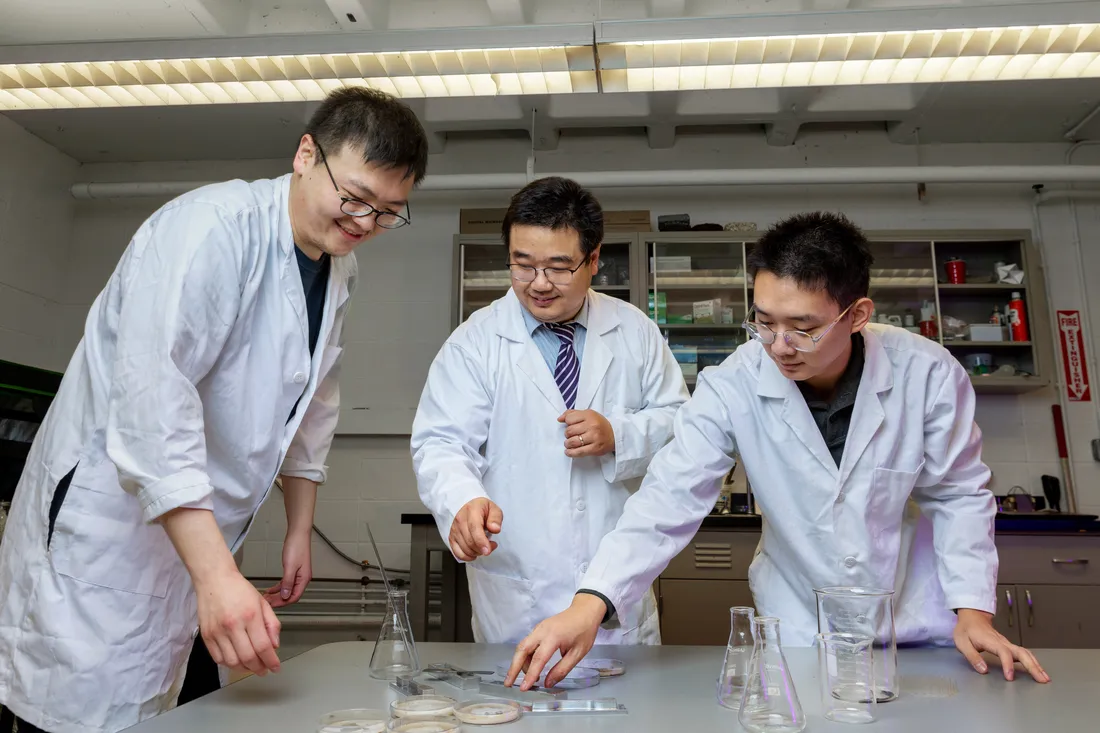

Professor Zhao Qin (center) works with graduate and undergraduate students to create a holistic model of mushroom mycelium at the molecular level, providing insight into mycelium’s potential for large-scale architectural uses.

When Zhao Qin and Nina Sharifi arrived at Syracuse University as new faculty members, they each knew interdisciplinary collaboration would be essential to their goals. Sharifi, a professor in the School of Architecture, was excited about the possibility of using renewable materials in building construction. Qin, a civil and environmental engineering professor, wanted to explore structural uses of materials produced by animals, plants or fungi.

“I kept thinking, ‘What kind of biomaterials can allow us to scale from nanoscale materials study to civil engineering applications, like infrastructure or large-scale designs?’” says Qin, who came to Syracuse’s College of Engineering and Computer Science in 2019 after earning a doctorate and working as a research scientist at MIT studying the mechanics of microscopic protein networks.

Qin and Sharifi found common ground in mycelium, a root-like fungal biomaterial produced during mushroom growth. Mycelium forms a fibrous network beneath the soil and is essential to plant growth and health. Its strands bind to plant waste, creating a composite that shows tremendous promise as a sustainable building material that can take the form of foam, panels or solid brick, with insulating properties.

Mycelium is a binder, but it also has this resilience and strength to it. If you change the way it’s grown, it can be incredibly dense or it can be light and foamy and diaphanous.

Professor Nina Sharifi

Conventional building materials like steel and concrete are energy-intensive to produce and transport, while synthetic plastics are made from crude oil, and adhesives used in fiberboard can release toxins over time. Mushroom mycelium, in contrast, is lightweight, biodegradable and nontoxic—as well as strong, durable and quick to regenerate.

Mycelium research is in its infancy, so the field is ripe for discovery. In early 2020, architecture professor Daekwon Park formed a Mycelium Research Group with Sharifi, opening the door to Sharifi’s collaboration with Qin. The group included Syracuse biology professor Scott Erdman and mechanical and aerospace engineering professor Jeongmin Ahn, who were also eager to uncover mycelium’s possibilities. Qin joined their team, intent on providing a deeper understanding through microscopic-level research.

In 2022, Qin was a winner of the National Science Foundation (NSF) CAREER Award, which recognizes faculty early in their careers for outstanding research. With a $600,000 grant, he is conducting foundational research that could inform the architects’ uses of mycelium.

Modeling at the Microscopic Scale and Up

Qin’s goal is to develop a holistic model of mycelium and its function, starting with an understanding of properties at the molecular level. “We want to generate knowledge from the fundamental scale and up that can provide multiscale insight and a reliable ‘recipe’ to allow anyone to produce biomaterials that would solve large-scale requirements,” he says.

Mycelium samples grow on a layer of woody debris, and researchers manipulate growth conditions in a climate chamber to produce desired characteristics.

His research involves both physical lab experiments and computational modeling. “There are a lot of variables,” explains Qin, whose lab houses a climate chamber for growing mycelium samples on a layer of woody debris. Within the chamber, he manipulates variables to produce desired characteristics: temperature, humidity and carbon dioxide levels; different mycelium species; and various types of wood that can influence mycelium growth and the mechanical properties of the finished product, such as density, lightness or strength.

Graduate and undergraduate students work closely with Qin on these experiments, testing different types of plant material on which mycelium can grow. “We use oak wood and coconut fibers to grow mycelium and make dog-bone-shaped samples for tests because the long fibers may provide useful properties when combined with the mycelium,” explains doctoral student Libin Yang.

Qin and his team examine the mycelium-and-wood samples using a scanning electron microscope and an atomic force microscope available through the University’s BioInspired Institute, which supports research addressing global challenges in health, medicine and materials innovation. “That kind of equipment is expensive for an individual lab, but I benefit from the shared facilities,” says Qin, who uses the microscopic images to understand how the mycelium fibers interact with wood fiber.

We’ve learned from each other, and we are working collaboratively at multiple scales.

Professor Nina Sharifi

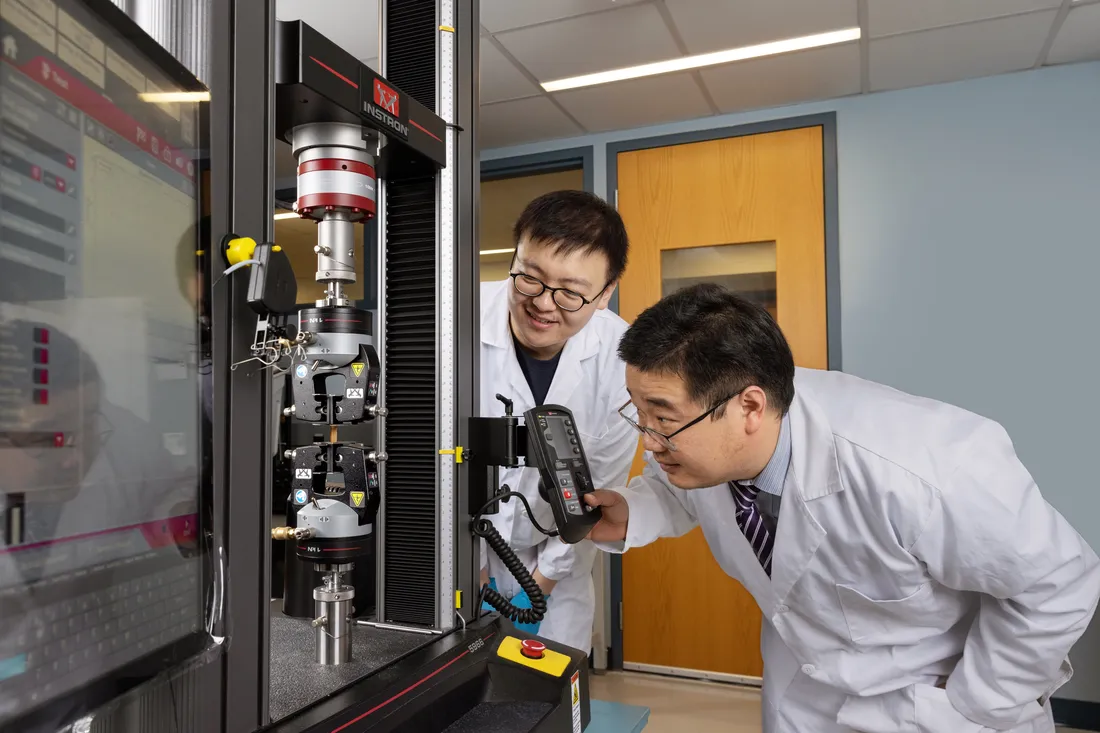

After harvesting the samples, the team heats and compresses them to form a dense, solid material—the building blocks for larger scale applications. They test the strength of these samples by stretching them mechanically to measure the amount of force needed to break them.

Throughout the process, they employ a data-driven model that tracks the outcome of each physical experiment to optimize the design. “We correlate those controlled conditions to the performance of the material at the end of the day,” Qin says. “Once we’re happy with the outcomes the model predicts, we can easily tune the variables to get a map that tells us the direction to go in the experiment.”

The Shape of Things To Come

Qin and doctoral student Libin Yang test the strength of mycelium samples using specialized equipment that measures the amount of force needed to break them.

Qin’s foundational research sheds light on the breadth of architectural possibilities. “There’s a lot to be learned about the filaments that make up mycelium—how they grow, the order of the structures they create,” Sharifi explains. “That influences what happens at the scale of a brick or a sheet material in a building.”

Sharifi describes mycelium’s properties with a sense of awe. “Mycelium is a binder, but it also has this resilience and strength to it. If you change the way it’s grown, it can be incredibly dense or it can be light and foamy and diaphanous.”

She recalls her excitement during early conversations with Park as they discussed the potential range of mycelium’s practical uses. “He brought so many great ideas to the table: deployable structures, emergency structures—or the idea that you could carry a building in a backpack to a site.”

Park is similarly inspired by mycelium’s versatility. “It has this bouncy quality to it, so it can be used as bomb shelter material,” he says. It can also be used to prevent soil erosion. “For unstable soil, you’d apply agricultural waste and then grow mycelium on it, and the mycelium fibers hold the soil together,” Park explains.

Once we’re happy with the outcomes the model predicts, we can easily tune the variables to get a map that tells us the direction to go in the experiment.

Professor Zhao Qin

The collaboration with Qin is expanding the group’s understanding of how manipulating mycelium fibers at the molecular level can influence its physical properties at a structural scale. “We’ve learned from each other, and we are working collaboratively at multiple scales,” Sharifi says. “We’re learning from the outcomes, and we’re just at the beginning.”